Creating spaces for living, working and meeting

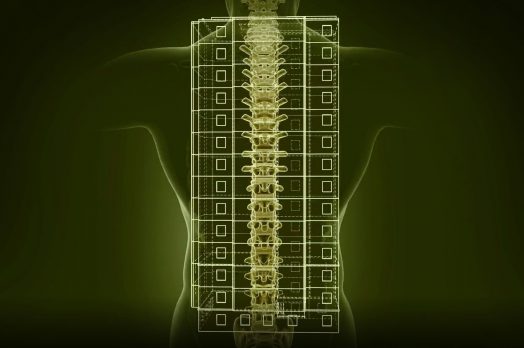

Imagine the world’s greatest football stadiums. Think of university buildings, hospitals, logistic centers, and parking garages. Then think of all types of residential buildings and even supply systems. There you have the backdrop of our lives: and a good idea of buildings where precast concrete elements, such as hollow core slabs and readymade sandwich walls, contribute to faster, stronger, more cost-efficient, and more sustainable construction.

Precast concrete can be used for most structural systems and can be combined with other building materials. It offers endless design variations and can realize the most spectacular architectural vision. Add to that the inherent high quality, safety and longevity derived from being made in a controlled industrial process, and you have a solution that will serve you and future generations well, without requiring excessive renovation or maintenance.

Planning and design

Precast concrete gives architects, property developers, and owners a unique combination of control and flexibility. Based on known, safe, and defined core components, the sky is the limit for using graphical and visionary building materials on surfaces facades, or as part of the concrete finishing.

And the strength of precast concrete gives you increased flexibility for future layout adaptations.

Efficiency

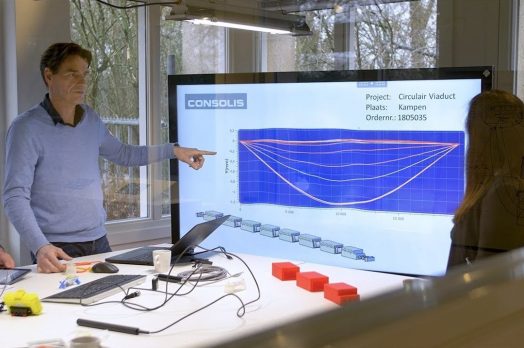

Produced off-site under controlled conditions, precast elements guarantee quality and predictability and ensure that components are thoroughly verified and inspected. It also allows for efficient and just-in-time project logistics.

At the building site, precast concrete will decrease installation time, increase site safety, reduce labor needs, and minimize the dependency on weather conditions to drive progress.

Environmental impact & economics

Our precast elements are produced in a controlled factory environment by trained personnel.

The materials used are designed, validated, and selected after applying stringent quality controls, allowing for efficient use of resources and full adherence to all relevant standards.

Precast concrete requires significantly less cement compared to traditional concrete and reduces CO2 emissions by 40 percent. By investing in research and innovation, we will continue to introduce more sustainable products, further reducing our impact. We are committed to achieving climate-neutrality in all products and productions.